Automation and Manufacturing: The Perfect Pair?

Times are changing. Handmade products and manual processes are things of the past. Going into the end of 2023 and early 2024, manufacturers are faced to conform to new industry practices or be left out.

Understanding the relationship between manufacturers and automation, the benefits, and how your company can begin automating practices is essential to remain relevant in an increasingly competitive environment.

How are Manufacturers Using Automation?

Manufacturers are using automation on all fronts. First, backend office reporting is being overhauled with accounting software founded on automation. Real-time bank feed updates, creating flexible budgets, and generating up-to-date forecasts are all ways that automation is changing how accounting is done in manufacturing businesses.

Physical product production is also seeing advancements with automation. Manufacturers are able to generate digital mockups with a few clicks, send those plans to machines, and wait for the product to be created. Most robots now have automation capabilities, alleviating the burden on your team.

Automation is also changing the entire supply chain. Manufacturers can automate the entire process from start to finish. For example, software creates a product template that a machine then produces. Customers place an order which gets routed to a logistic company for pickup and delivery. Instead of being required to control the entire process, manufacturers are able to pass a majority of the burden off to automation resources.

What are the Benefits of Automation in the Manufacturing Process?

Automation in the manufacturing process poses undoubted benefits. Businesses are able to maximize their bottom-line number by passing the labor burden to robots and specialized machines. The upfront costs of robots and equipment that have automation capabilities are minimal compared to the long-term value.

Not to mention that automation allows businesses to increase capacity. There are no longer time and labor constraints, as machines can work around the clock producing products. This frees up more time for your team to pursue other value-added activities, such as adding a servicing segment or creating new products.

How to Implement Automation

Implementing automation is essential for manufacturing businesses going into the next few years. First, you need to evaluate your business’s current needs. In what ways could automation change your processes? Once you determine inefficiencies, you can search for solutions.

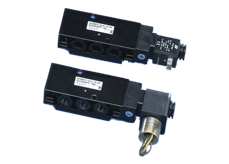

One solution might be purchasing newer machinery that leverages automation capabilities. It’s hard to automate processes without the right robotics or equipment working alongside you. If you don’t have the budget to purchase a new piece of machinery, consider buying used from a reputable dealer, like IMS Supply.

Next, you want to implement the machinery, equipment, and software into your general business practices. Offer training on best practices and consistently evaluate the use of automation in your company to pinpoint areas of improvement. Taking your business to the 21st century requires consistent oversight.

Summary

Are you ready to leverage automation in your manufacturing business? Automating and manufacturing are the perfect pair. It’s now adapt and overcome or be left out.

About IMS Supply: IMS Supply is a leading distributor of maintenance, repair and operations (MRO) products and services with facilities in East and West Michigan and Kentucky. Through our MRO Asset Recovery Program we stock hard to find parts and supplies from thousands of different manufacturers at prices up to 70% less than MSRP. Contact us today to find out how we can help your business.